DFS is known as an innovator and our product solutions deliver leading-edge enhancements to process utilities for many of today's high-tech industries.

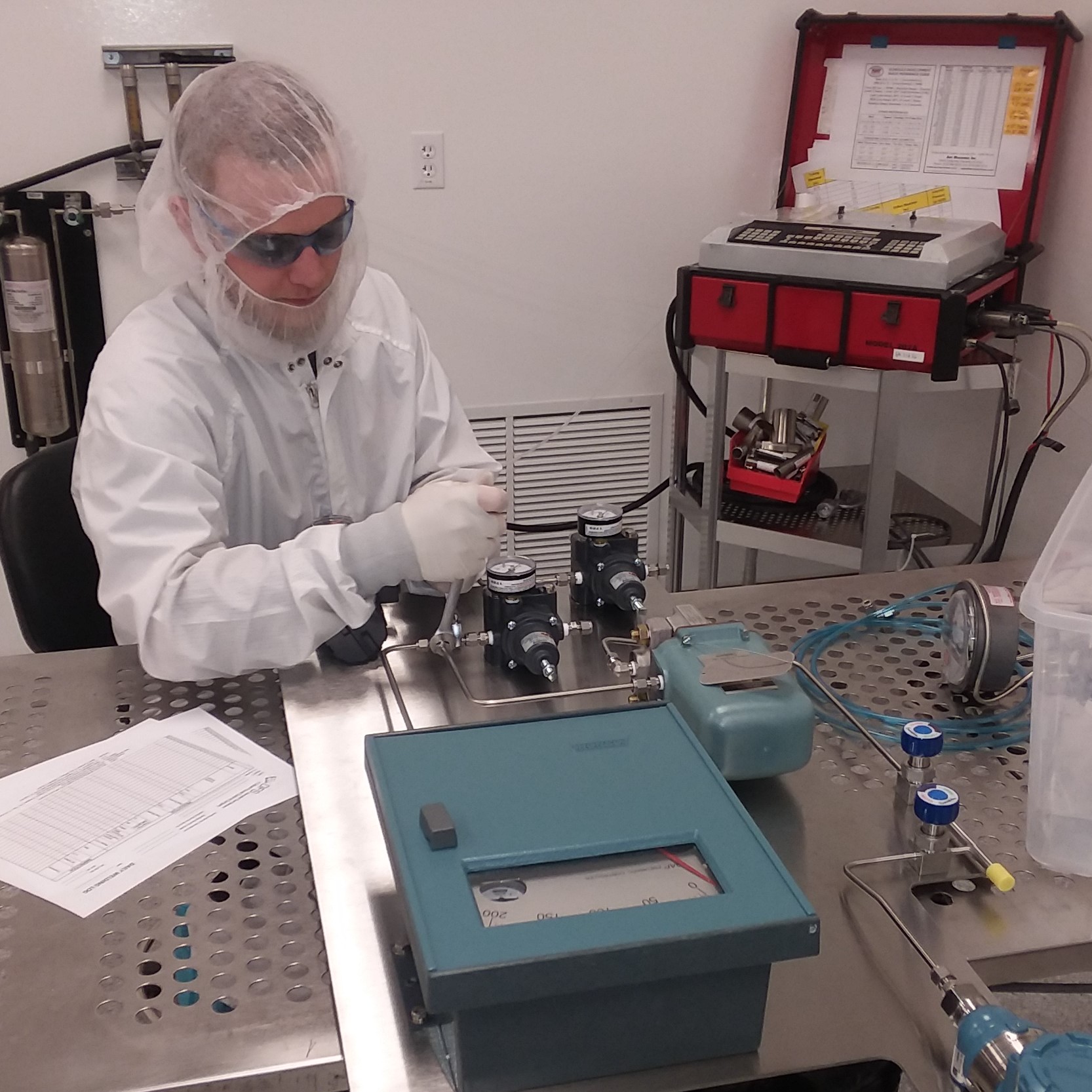

Our fabrication facility totals 32,000 square feet including over 1,740 square feet of clean room space. We have one fixed and one portable clean room which are certified to ISO standard 14644 at either ISO 6 (Class 1,000) or ISO 7 (Class 10,000). Our clean room is equipped with modern tools and equipment for automatic tube-cutting and facing, high-purity welding, IR welding, tube bending, pulled-header fabrication, final testing and certification. Our rooms are also equipped with a dedicated purified and filtered weld argon system to ensure the cleanliness and integrity of all DFS fabricated assemblies.

DFS's in-shop fabrication capabilities and on-site turnkey installation services include design, material acquisition, fabrication, quality assurance, start-up/commissioning and document turnover packages.

- DFS complies with SEMI, cGMP, and BPE industry standards and regulations

- We are third-party certified in orbital and grooved welding

- Our testing includes ASME bend and tension

- ISO Class 7 (Class 10,000) prep area

- iso Class 6 (class 1,000) clean room

- Welding assembly and packaging area

- 25,000-square-foot dedicated manufacturing space

- Certified welding test facility

- Automatic orbital weld facility

- cGMP-compliant facility

For more information: 208.489.0053 or email info@dfsolution.com